Metric tube fittings are progressively gaining acceptance around the world, in part due to the metrification of hydraulic systems by globally operating OEMs. STAUFF Connect Metric Tube Fittings offer the universal standard for fluid power applications. These tube fittings can be easily and quickly assembled, only requiring a few standard wrenches. STAUFF offers a wide range of sizes from 4 mm to 42 mm in outer tube diameter, making them easy to interchange with other tube fitting systems. With an optimized inner contour and design, they provide ideal flow rates without the excessive generation of vibration, noise, or heat.

STAUFF offers an extensive range of metric tube fittings made of steel, all in accordance with ISO 8434-1 and DIN 2353. The STAUFF Connect product line includes:

- 24° Cutting Ring Fittings

- 24° Taper Fittings with O-Ring (DKO)

- 24° Weld Cones with O-Ring

- 37° Fllared Tube Fiittings

Special product types and sizes, as well as alternative materials, material combinations, and surface coatings deviating from the standards can be supplied on request. STAUFF Connect fittings are manufactured using premium quality steel which yields a range of working pressures that exceeds standards.

All carbon steel tube connectors have a Zinc/Nickel surface coating. This coating has an overall thickness of 8 μm and offers excellent surface protection. Carbon Steel with Zinc/Nickel coating connectors are protected against corrosion and are resistant to red rust and base metal corrosion with at least 1200 hours of resistance. This was confirmed by testing in the salt-spray chamber according to DIN EN ISO 9227. Including 4 layers of steel, zinc/nickel, passivation, and sealing, the surface finish is a bright semi-gloss that is comparable to stainless steel.

Innovation is incorporated into every aspect of our metric fittings from the cutting rings to the forming and assembly tools. STAUFF Connect exceeds expectations by providing competitive pricing without compromising on premium quality.

STAUFF tube connectors can be used in a variety of different industries, but are especially seen being used in manufacturing, agricultural, construction, and mining equipment.

STAUFF Connect Metric Fittings

24° Fittings & 37° Fittings

24° Fittings General Information

These fittings are commonly used and are the established industrial tube connector systems worldwide. While they are not the norm in North America and Australia, they are progressively gaining more and more acceptance as OEMs are introducing metrification to their hydraulic systems. These connectors are extremely easy to combine with other tube fitting systems, even hoses can be connected without difficulty with standard wrenches for assembly. They utilize a metallic sealing surface and are characterized by a 24-degree conical bore. The opposite end of the connector has a variety of connection types:

- Male and female threaded or welded studs

- Various options such as, straight fittings, elbows, tees, crosses, unions, studs, bulkheads, and adjustable fittings are available

The 24° Tube Fitting System is available in the Extra-Light (LL), the Light (L), and the Heavy (S) Series, which provide sufficient pressure ratings and maximum leak-tightness up to nominal pressures of 800 bar (11600 PSI) for each application. These tube fittings are specified in the ISO 8434-1 and the DIN 2353 standards. Due to their design, being small and compact compared to other tube fitting systems, these tube fittings are perfect for applications with space considerations.

Key Characteristics of 24° and 37° Fittings

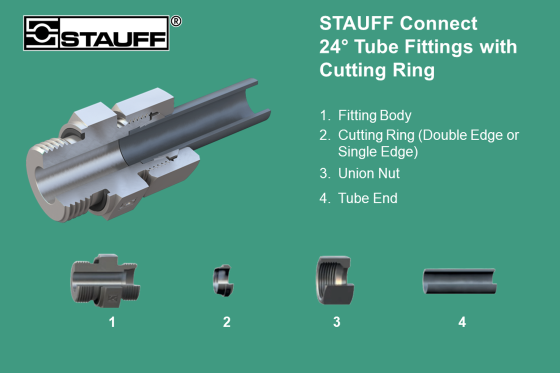

STAUFF Connect 24° Cutting Ring Tube Fittings

- These fittings have been developed for a reliable, leak-free connection of tubes. Fittings with a cutting ring cut into the tube when tightened, therefore ensuring the necessary force and form closure in the cutting area and a uniform distribution of force. These fittings fully comply with the latest versions of the ISO 8434-1 and the DIN 2353 standards.

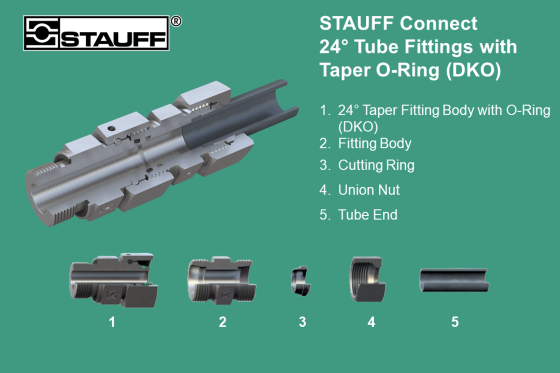

STAUFF Connect 24° Taper Fittings with O-Ring (DKO)

- Due to the 24° taper on the fitting body itself, these fittings are an improved version of the previously available adjustment standpipe tube fittings with factory-assembled cutting rings and union nuts. The retention function is secured by a special union nut with a wire-pin in a groove. The embedded O-Ring on the 24° taper ensures a high level of protection against leaks. Due to their full compliance with ISO 8434-1 and the DIN 2353 standards, STAUFF Connect 24° Taper Fittings with O-Ring (DKO) are completely interchangeable with conventional adjustable standpipe tube fittings.

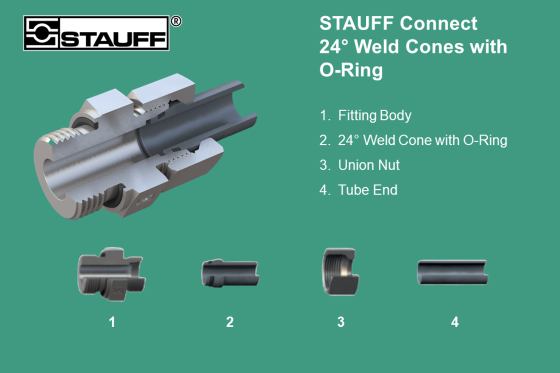

STAUFF Connect 24° Weld Cone Fittings with O-Ring

- The 24° Weld Cone Fittings with O-Ring are directly welded to the tube end. They represent a supplement to the usual range of tube fittings. However, they are seen as a special solution due to the tube preparation, assembly, finishing, and testing. Typical applications are in power stations, heavy industry and industrial plant construction.

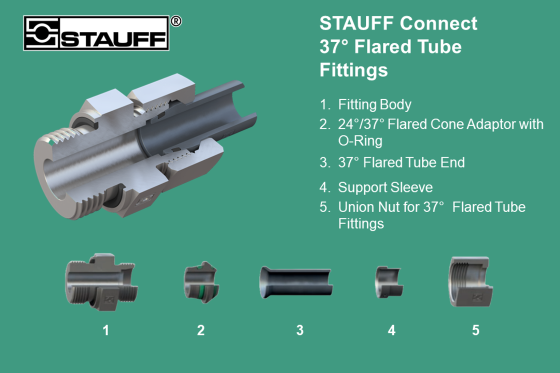

STAUFF 37° Flared Tube Fittings

- The 37° fittings have been developed for a reliable and leak-free connection with a 37° flare with conventional fitting bodies with a 24° cone. Due to the metallic/elastomer sealing at the contact points, to the fitting body and the tube, efficient sealing is ensured, even if there are vibrations and pressure fluctuations or peaks. These fittings can be used in applications with nominal pressures up to 500 bar (7250 PSI) on the light series or up to 630 bar (9135 PSI) on the Heavy Series. Common applications for this fitting are concrete pumps and hydraulic presses.

These premium tube fittings can be quickly and easily assembled. All that is required is a few standard wrenches for assembly and disassembly with no requirement of tedious and expensive staff training or special tube treatment.

The Tube Fitting System is available in the Extra-Light (LL), the Light (L), and the Heavy (S) Series coming in a variety of sizes with an outside diameter ranging from 4mm to 42 mm. This helps provide a maximum leak-tightness up to nominal pressures.

STAUFF Connect Fittings have an optimized inner contour and design, which contributes to the ideal flow rates without the excessive generation of vibration, noise, or heat.

Because of the design, the material is clearly visible in front of the cutting ring after assembly, making it easy to confirm proper assembly of the 24° tube fittings.

STAUFF Connect Tube Fittings are easy to connect with other tube fitting systems. Even hoses can be connected without difficulties.

All Carbon Steel fittings have a Zinc/Nickel coating, which provides excellent surface protection against corrosion and resistance to rust.

Straight Couplings

- Straight couplings or unions allow for the joining of two metric tubes. Either two tubes of the same diameter, or with a Straight Reduces Coupling style, two tubes of different diameter.

Male Stud Couplings

- Male Stud Couplings are used to connect a metric tube to a threaded port. In addition to metric ports, couplings are available to be used with BSP, NPT, and UNF threaded components.

Elbow Fittings

- Elbow fittings join two metric tubes together at a 90-degree angle and allow for much more compact installations compared to bending a radius in the tube.

Tee Fittings

- Tee fittings join together three metric tubes at 90 degrees. Standard versions connect three tubes of equal diameter, Tee Reducer fittings can accommodate up to three different diameters.

Bulkhead Fittings

- Bulkhead fittings, either straight or with a 90-degree elbow, are a type of connector used in hydraulic systems to pass fluid through a barrier, such as a wall or partition. It is used to connect seamless hydraulic tubing to a machine, motor, piece of equipment, or bulkhead.

Order STAUFF Connect Metric Fittings Online

New and existing customers can use the STAUFF Online Shop to order Metric Fittings along with the other products STAUFF has to offer. With a secure checkout process you can get everything you need quickly, easily, safely, and inexpensively.

The complete range of products from STAUFF includes more than 50,000 individual standard hydraulic components in 10 product groups. STAUFF also guarantees prompt service for custom-designed systems and special solutions according to customer's requirements.

Have any questions or need help? Contact a STAUFF representative through Live Chat or the Contact Form for quick and quality support to help guide you in your purchase.

If you are interested in learning more about STAUFF, sign up for the newsletter below and stay up to date with all news, updates, and product information directly from STAUFF.

STAUFF Online Page-Flip Catalog

Navigate and search content, forward via email, print, and download in PDF format.